To resolve the automation and control issues, industries use the ever changing technologies in control systems for efficient production or manufacturing processes. These requires the high quality and reliable control systems. New trends in industrial automation deals with latest control devices and communication protocols to control field devices like control valves and other final control elements. Some of the smart devices or instruments used in automated industry has the ability to control the processes and also communication capabilities without interfacing to other field level control devices like PLC’s.

What is Industrial Automation?

Industrial automation is the use of control systems, such as computers or robots, and information technologies for handling different processes and machineries in an industry to replace a human being. It is the second step beyond mechanization in the scope of industrialization. Industrial automation facilitates to increase the product quality, reliability and production rate while reducing production and design cost by adopting new, innovative and integrated technologies and services.

Automation takes a step further mechanization that uses a particular machinery mechanism aided human operators for performing a task. Mechanization is the manual operation of a task using powered machinery that depends on human decision making. Industrial Automation is the replacement with computers and machines to that of human thinking. The word Automation gives the meaning ‘self-dictating’ or ‘a mechanism move by itself’ that derived from the Greek words Auto and Matos where auto means self while Matos means moving.

Why Industrial Automation?

- To increase productivity

Automation of factory or manufacturing or process plant improves production rate through a better control of production. It helps to produce mass production by drastically reducing assembly time per product with a greater production quality. Therefore, for a given labor input it produces a large amount of output.

- To provide optimum cost of operation

Integration of various processes in industry with automated machineries, minimizes cycle times and effort and hence the need of human labor gets reduced. Thus the investment on employees has been saved with automation.

- To improve product quality

Since the automation reduces the human involvement, the possibility of human errors also gets eliminated. Uniformity and product quality with a greater conformity can be maintained with automation by adaptively controlling and monitoring the industrial processes in all stages right from inception of a product to an end product.

- To reduce routine checks

Automation completely reduces the need for manual checking of various process parameters. By taking advantage of automation technologies, industrial processes automatically adjusts process variables to set or desired values using closed loop control techniques.

Hierarchy of Industrial Automation

- Field level

- Control level

- Programmable Logic Controllers (PLC’s)

- Supervising and Production Control Level

- Information of Enterprise Level

Structure of Industrial Automation

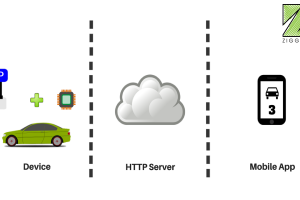

Sensor level is also called as process layer. It uses the sensors and actuators to get the values of the process variables in continuous or periodical manner. These act as eyes and arms of the industrial processes. Some of these instruments include pneumatic instruments, smart instruments, etc. Automation control level or control layer uses industrial control devices like PC’s/PLC’s/DCS, etc. This level utilizes the various embedded processors, PID algorithms to control the process. Supervising level or SCADA layer gets lots of channel information and stores the data in the system database. Enterprise level performs the tasks like scheduling, orders and sales, product planning, etc.

Types of Industrial Automation

- Fixed Automation – In this sequence of operations to be performed are fixed by the equipment configuration. It is used in high volume production with dedicated equipment. Examples of this automation system are automated assembly lines, distilled process, machine transfer lines.

- Programmable Automation – In this, sequence of operations can be changed by changing the program. Sequence of operations is varied based on the different product configurations. Also new programs can be entered into the programmable devices for the new products. This type of system is used in batch processes, steel rolling mills, industrial robots, etc.

- Flexible Automation – It is the extension for the programmable automation. This offers a greater flexibility to deal with product design variations. Operators can give commands in the form of codes in the computer program if wants to change the sequence of the process.

- Integrated Automation – In this type total system is fully automated under computer control. Starting from designing process to the dispatching, whole system is completely automated. Even the equipment is handled by the robots. This system is used in computer integrated manufacturing systems.

Advantages of Industrial Automation

- High Productivity – Although many companies hire hundreds of production workers for a up to three shifts to run the plant for the maximum number of hours, the plant still needs to be closed for maintenance and holidays. Industrial automation fulfills the aim of the company by allowing the company to run a manufacturing plant for 24 hours in a day 7 days in a week and 365 days a year. This leads to a significant improvement in the productivity of the company.

- High Quality – Automation alleviates the error associated with a human being. Further, unlike human beings, robots do not involve any fatigue, which results in products with uniform quality manufactured at different times.

- High flexibility – Adding a new task in the assembly line requires training with a human operator, however, robots can be programmed to do any task. This makes the manufacturing process more flexible.

- High information accuracy – Adding automated data collection, can allow you to collect key production information, improve data accuracy, and reduce your data collection costs. This provides you with the facts to make the right decisions when it comes to reducing waste and improving your processes.

- High safety – Industrial automation can make the production line safe for the employees by deploying robots to handle hazardous conditions.

Conclusion

Industrial automation has recently found more and more acceptance from various industries because of its huge benefits, such as, increased productivity, quality and safety at low costs.